CW735 Rubber Only Bush

This rubber only bush has no metal parts, and requires an interference fit on one or both inner and outer interfaces. This interference fit holds ...

View full detailsExperts in design, manufacture & supply of rubber bushings, anti-vibration mounts & moulded rubber products

Experts in design, manufacture & supply of rubber bushings, anti-vibration mounts & moulded rubber products

Example torsion bush bonded in place - developed for a low volume automotive customer

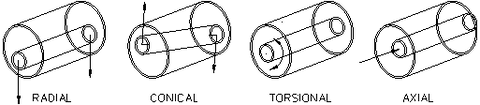

A wide range of standard Torsion Bushes are available providing characteristics to suit diverse applications. They are commonly used in automotive and rail applications for suspension system linkages or leaf spring mounting, where some degree of movement is desirable. This bush design provides for displacement in a combination of radial, axial, torsional or conical loadings (see diagrams below)

Bushes are placed at the pivot points for any of the following reasons:

The degree of displacement for a 2 tube system and based on a constant elastomer can be designed-in by adjusting the basic parameters of length plus inner and outer tube diameters as follows:

Radial

This relates to displacement such that the inner tube is moved towards the outer tube whilst remaining axially parallel to it such that the thickness of rubber is reduced uniformly on one side. The radial displacement can be decreased by increasing the projected area (diameter of inner tube x length of outer tube). This can be facilitated by increasing the overall length of the bush or by increasing the outside diameter of the inner tube. When only radial loading is anticipated, these bushes will withstand significant shock loads in excess of normal rated load for the size (up to 5 times rated loading) However, if conical loading is anticipated in addition to radial loading, the nominal rated loading must be reduced. Also if cyclic loading is anticipated, the load catered for should be at least halved.

Torsional

When one tube is rotated relative to the other whilst remaining axially parallel, this implies a torsional load. Reducing the thickness of the elastomer will reduce the angular displacement for a given torque (increasing the inner tube’s outer diameter or decreasing the outer tube’s inner diameter) or by increasing the overall length of the bush. Typically the maximum frequency of torsion loading accommodated is 8Hz (480 cycles per minute) and this would be for small angular movements up to +/-5 ° For lower frequencies +/-40° can be accommodated for some bushes where the rubber thickness allows.

Conical

If an angle is developed between the axes of the two tubes such that they are no longer parallel, this is a conical load. The displacement from such loads can be minimised by reducing the thickness of the elastomer or by increasing the length of the bush as above. Applications should limit the angular movement such that the thickness of elastomer at the end of the outer sleeve is not reduced by more than 30%. Clearly, greater conical movement is provided by a greater thickness of elastomer, which in turn can be determined by changes in tube diameters.

Axial

When the ends of the tubes are displaced relative to their no-load position whilst the axes remain parallel, this is an axial load. The displacement can be reduced by reducing the thickness of the elastomer or by increasing the length of the bush as above. Design loads should be kept to a maximum of 10% of the rated radial load.

The deflection parameters can also be modified by altering the hardness of the elastomer (harder reduces deflection) or by inserting an intermediate tube which reduces deflection in all directions as for example in our TB (triple bonded) bush type.

The outer tube is either clamped in place or is an interference fit in a machined housing requiring insertion using a mechanical or hydraulic press. The inner tube is typically held in place by a clamping bolt which is tightened to sufficient torque to prevent the inner tube from rotating in use under the forces likely to be experienced.

In most applications bushes are intended to be a press fit in a bore. In this case the following bore tolerances should be applied: The bush diameter should be taken as its nominal size – mid-tolerance.

Note: where the bush is to be inserted into a rolled spring eye, the interference is greater due to the yielding of the spring eye.

|

Outside diameter of bush (mm) |

Bore limits from nominal bush O/D |

Rolled Spring eye Bore |

SAB Style Bushes |

|

6 to 23 |

-0.04 / -0.06 |

-0.25 / -0.50 |

-0.25/ - 0.35 |

|

24 to 40 |

-0.05 / -0.08 |

-0.40 / -0.70 |

-1.00 / -1.10 |

|

41 to 50 |

-0.06 / -0.09 |

-0.9 / -1.10 |

-1.50 / -1.60 |

|

51 to 70 |

-0.08 / -0.0.10 |

-1.00 / -1.40 |

-1.70 / -1.80 |

For SAB style bushes without the outer steel tube, the degree of interference is also much greater. This provides for security of installation and also has the effect of stiffening the bush due to the compression of the rubber during assembly.

The torsion bushes on most cars consist of a larger steel sleeve mounted inside the control arm, with a smaller steel sleeve inside for the mounting bolt, held in place with rubber which was bonded and vulcanised in place. The sleeve is fixed into the arm, and the inner tube held tight by the mounting bolt. As the arm moves, the rubber material gives way to the shear forces, allowing smooth movement of the arm without any sliding motion or surface-to-surface friction and hence nothing to wear, squeak or rattle. Most modern rubber torsion bushes are double bonded (i.e. the rubber is chemically bonded to both metal surfaces during the curing (vulcanising) of the rubber. In some cases the outer surface is held in place by creating a significant interference fit during assembly of the bush. Such bushes are not intended to slide within the outer sleeve but allow for occasional extreme torsional overloading of the bush.

Inner & outer tubes are of steel which is zinc plated or ‘Sherardized’ and clear or yellow passivated. For the chemical bonding process, the bonded surfaces are further treated with special purpose priming and bonding agents. To achieve the required quality and ensure that the surfaces are not contaminated prior to bonding, the latter operations are under in-house control.

We have many off the shelf torsion bushes, but please contact us should you have a bespoke requirement, we can probably make it fairly easily.

Over the years, AVMR have supplied to many automotive manufacturers, many of whom have subsequently ceased production. The products listed below are some of the parts which have been supplied based on original vehicle manufacturer.

Parts currently supplied to OEM’s for current models are not available from AVMR – buyers should refer to the relevant manufacturer’s spares outlet.

This rubber only bush has no metal parts, and requires an interference fit on one or both inner and outer interfaces. This interference fit holds ...

View full detailsCopyright © 2024 Anti Vibration Methods (Rubber) Co. Ltd.