10080 Mounts

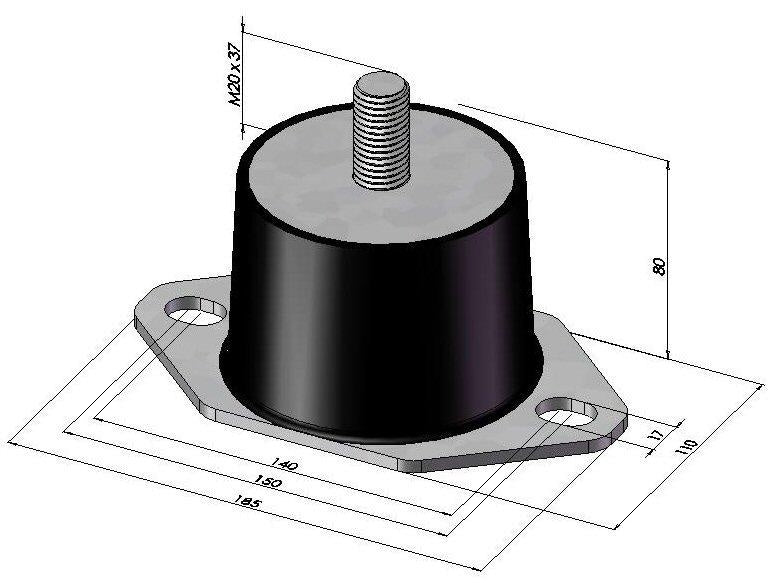

These large solid rubber mounts have a lower mounting flange with fixing slots and a load spreading top disc, both of which are chemically bonded to the rubber material.

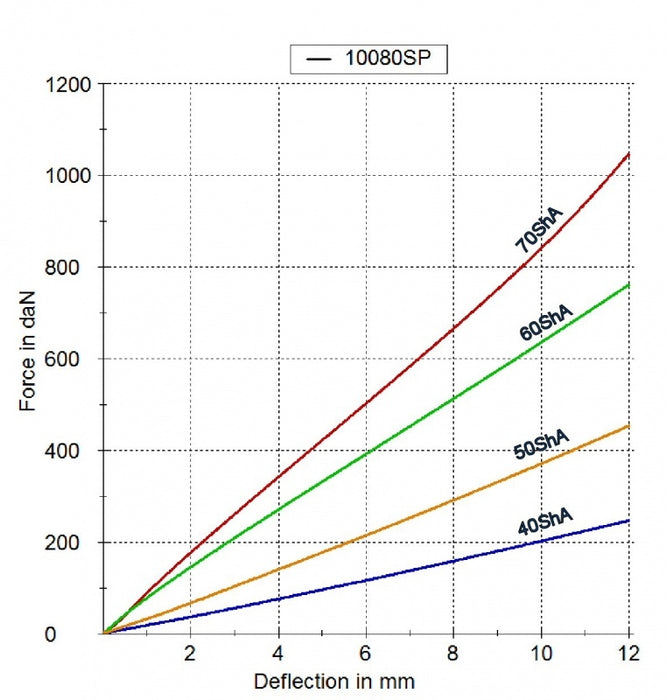

Stiffness (compression)

|

Guideline Max static compression load per mount (daN) |

Soft (/2 - 40Sh) |

175 (fairly soft laterally) |

Medium - Soft (/3 - 50Sh) |

275 |

Medium - Hard (/4 - 60Sh) |

475 |

Hard (/5 - 70Sh) |

650 |

When fitting the mount, the following points are important:

- The flanged plate (with through holes) should be fixed to a solid flat surface that provides consistant support across the whole surface of the plate.

- The supported load should cover at least 80% of the top plate

- The male thread is for tightening the load down to the mount and not for jacking up for height adjustment. Any Height adjustment should be provided using shims or washers.

These mounts are manufactured in the UK to a particularly high standard; Metals are bonded to rubber using a 2 layer bonding system (most manufacturers use a single layer system). The advantage of this approach is longevity of the bond, particularly in more environmentally challenging conditions. All rubbers used on standard products are designed to an MVEE (military) standard or an equivalent equivalent British Standard (e.g. BS1154).

Via special order, versions of this product are available with the following variations:

- 316 Stainless Steel

- M10 - M24 male or female thread options

- Various rubber colours and types

Standard production is based on Sherardized steel plates and M20 threads.